T: +86-512-66294696

E: sales@tzjmachine.com

E: sales@tzjmachine.com

Add: No.20, Guangdian Road, Guangfu Town, Wuzhong District, Suzhou, China

Views: 0 Author: Site Editor Publish Time: 2025-11-21 Origin: Site

In modern manufacturing, precision is everything. How do industries ensure the performance and durability of their valve systems? The answer lies in valve grinding machines. These machines are now essential for maintaining the high standards required in today's manufacturing.

In this article, we will explore why valve grinding machines are becoming indispensable for industries demanding precision. You’ll learn how they ensure performance, longevity, and efficiency in various sectors.

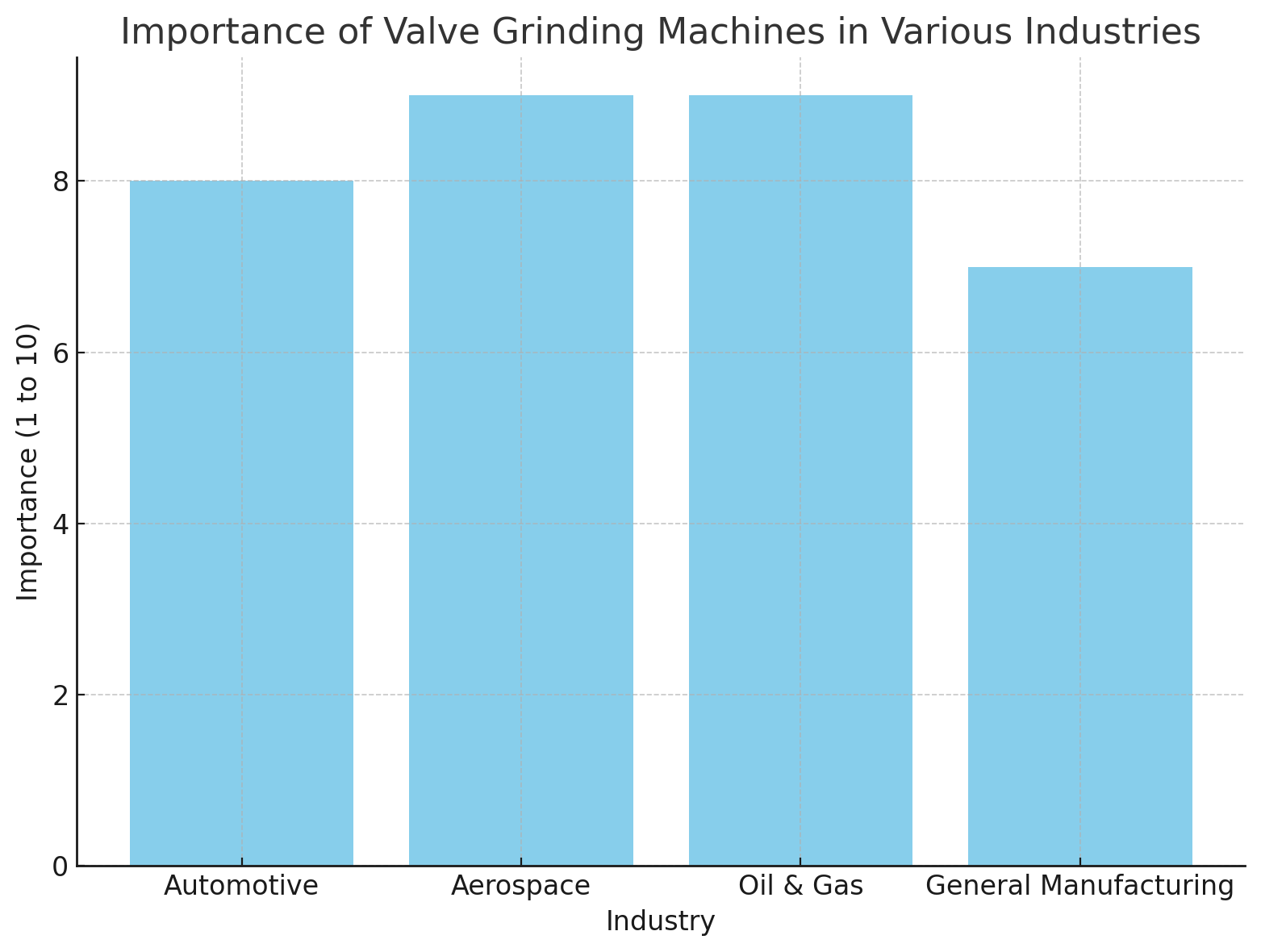

Modern industries, especially those in sectors like automotive, aerospace, and oil & gas, are experiencing a shift toward higher performance standards. The increasing complexity of systems, coupled with the need for more efficient and reliable operations, has made precision a non-negotiable factor in manufacturing. For instance, valves, which control the flow of fluids or gases, must operate under high pressure and extreme conditions without leaking or malfunctioning. To meet these rigorous demands, manufacturers need to ensure that valves meet strict tolerance and geometry requirements.

Valve grinding machines help meet these precision requirements by ensuring that valve surfaces are ground to exact specifications. These machines are designed to create the smooth, perfectly shaped surfaces that allow valves to form a tight seal, preventing leaks and ensuring the smooth operation of entire systems. As industries push for better performance, valve grinding machines have become indispensable in maintaining and repairing valves to meet these ever-evolving standards.

Advanced valve systems, such as hydraulic and pneumatic valves, have further increased the need for precision. These systems, commonly found in critical applications like aerospace, automotive, and industrial machinery, rely on precise valve sealing to function optimally. A small deviation in the valve's shape or surface can cause significant performance issues, such as leaks, reduced efficiency, or system failures.

Valve grinding plays a crucial role in maintaining the integrity of these systems. By refining valve surfaces to ensure a precise fit with the valve seat, grinding machines help minimize leakage and improve performance. Furthermore, valve grinding extends the life of valves, reducing the need for frequent replacements and costly repairs. As industries continue to rely on increasingly complex and high-performance valve systems, the role of valve grinding machines becomes even more vital.

Valve grinding machines are specialized tools used to precisely grind the sealing surfaces of valves. These machines are designed to remove material from the valve surfaces, ensuring they have the exact shape, smoothness, and dimensions necessary for optimal performance. Valve grinding machines can be used to grind various valve types, including engine valves, industrial valves, and control valves, ensuring they meet stringent performance standards.

The basic function of a valve grinding machine is to remove imperfections from the valve surfaces, which are critical for achieving a proper seal when the valve closes. These imperfections may include wear, corrosion, or surface damage that can result from the valve's normal operation or from external factors such as harsh environments or excessive pressure. By ensuring that the valve surfaces are smooth and uniform, valve grinding machines improve sealing, reduce wear, and extend the overall lifespan of the valve.

Modern valve grinding machines come with several features that enhance their functionality, efficiency, and precision:

● Precision Control: Valve grinding machines are equipped with advanced control systems that allow operators to fine-tune the grinding parameters. This enables precise adjustments to achieve the desired surface finish and geometry.

● Adjustable Speeds: Many valve grinding machines feature adjustable speed settings that allow operators to select the ideal grinding speed based on the valve material and desired surface finish. This flexibility enhances the machine's versatility and efficiency.

● Customizable Designs: Valve grinding machines are often designed with modular components, allowing manufacturers to customize the machine based on the specific needs of the application. This ensures that the machine can handle different valve sizes, materials, and grinding requirements.

● Advanced Grinding Technologies: Innovations in grinding technologies, such as diamond abrasives and CNC-controlled grinding heads, improve the precision and speed of the grinding process. These technologies ensure that valve surfaces are ground to the highest standards with minimal human error and reduced downtime.

These features make valve grinding machines critical in maintaining the quality and efficiency of valve systems in modern manufacturing processes.

Feature | Description |

Precision Control | Allows fine-tuning of grinding parameters. |

Adjustable Speeds | Enables customization of grinding speed for different materials. |

Advanced Grinding Technology | Uses innovations like diamond abrasives for better precision. |

Modular Design | Offers flexibility for different valve types and sizes. |

One of the primary reasons for using valve grinding machines is to ensure proper valve sealing. A valve must create a tight seal against the valve seat to prevent fluid or gas leakage. If the sealing surfaces are not ground properly, even the slightest imperfection can cause leaks, leading to system inefficiencies or failures. Valve grinding machines remove the wear and damage from valve surfaces, ensuring that the sealing surfaces are smooth and perfectly shaped to fit the valve seat.

Maintaining precise valve geometry is essential for performance. If a valve is not properly ground, the seal may be compromised, leading to issues such as pressure loss, inefficient operation, or even catastrophic system failure. By using valve grinding machines, manufacturers can ensure that valves maintain their functionality over time, preventing costly repairs and downtime.

Valve grinding machines also help minimize wear and extend the lifespan of valves. Over time, valves can experience wear from regular use, corrosion, or exposure to extreme temperatures and pressures. This wear can lead to reduced sealing performance and increased maintenance requirements.

Grinding the valve surfaces restores their original geometry, helping to prevent further wear and damage. By regularly grinding valves as part of a preventive maintenance program, manufacturers can extend the life of their valves and reduce the need for costly replacements. This is particularly important in industries where downtime is expensive, and the cost of replacing valves can be significant.

In the automotive industry, valve grinding machines play a crucial role in maintaining and repairing engine valves. Engine valves are subjected to intense stress and wear, especially in high-performance engines. Regular grinding ensures that the valves remain in optimal condition, maintaining engine efficiency and preventing failures.

Valve grinding in automotive engines is particularly important for improving fuel efficiency and reducing emissions. A well-ground valve creates a better seal, ensuring that the combustion process is efficient and that no gases escape. This improves overall engine performance, reduces fuel consumption, and helps meet environmental standards.

The aerospace and oil & gas sectors demand the highest levels of precision and reliability from their valve systems. In these industries, valves must function flawlessly in extreme environments, such as high-pressure systems or harsh chemical conditions. Valve grinding machines are critical in ensuring that the sealing surfaces of valves are perfectly ground to withstand these conditions.

In aerospace applications, valve performance can directly affect the safety and efficiency of an aircraft. Similarly, in the oil & gas industry, valves control the flow of hazardous materials, making precision in valve sealing essential to prevent leaks and ensure safety. Valve grinding machines provide the precision needed to meet these high standards.

In general manufacturing and heavy machinery applications, valve grinding machines ensure that valves used in large industrial systems operate reliably and efficiently. These systems often operate under high pressure and demanding conditions, where valve failure can lead to significant downtime and maintenance costs.

Valve grinding machines help maintain the performance and safety of these systems by ensuring that the valves are properly sealed and functioning. Regular grinding extends the life of the valves, reducing the need for replacements and minimizing operational disruptions.

Industry | Application | Role of Valve Grinding Machines |

Automotive | Engine valve maintenance and repair | Ensures efficient engine performance and prevents failure. |

Aerospace | Aircraft valve systems | Meets high precision standards for safety and reliability. |

Oil & Gas | Control valves for high-pressure systems | Prevents leaks and ensures the smooth operation of critical equipment. |

General Manufacturing | Heavy-duty machinery and industrial systems | Ensures long-lasting and reliable performance under extreme conditions. |

The integration of smart technology and automation has revolutionized valve grinding machines. Modern machines feature digital controls, sensors, and IoT capabilities that allow for real-time monitoring and adjustments. These advancements improve precision, reduce the risk of human error, and enhance the overall efficiency of the grinding process.

Automated valve grinding machines can also optimize grinding parameters based on the valve type and material, ensuring that each valve is ground to the correct specifications without requiring manual intervention. This automation reduces labor costs, improves consistency, and increases throughput.

The development of advanced grinding technologies has further increased the need for valve grinding machines in modern manufacturing. New materials, such as diamond abrasives and high-performance grinding wheels, allow for more efficient and precise grinding. These innovations enable valve grinding machines to achieve even higher levels of accuracy and surface finish quality.

Furthermore, CNC-controlled grinding heads and multi-axis grinding systems allow for more complex valve geometries to be ground with high precision. These technologies ensure that valve surfaces are ground uniformly and meet the exact specifications required for optimal valve performance.

When selecting a valve grinding machine, several factors should be considered to ensure that the machine meets the specific needs of the application. Key considerations include:

● Valve Size and Material: The size and material of the valve determine the type of grinding machine needed. Larger valves may require more powerful machines, while smaller valves may require machines with more precise controls.

● Grinding Precision: The required level of precision depends on the application. For critical applications, such as aerospace or automotive engines, a higher level of precision is necessary.

● Machine Features: Look for machines with adjustable speeds, precision controls, and the ability to handle various valve types. Customizable machines offer more flexibility in meeting different grinding needs.

One common mistake when selecting a valve grinding machine is focusing too much on price and not enough on the machine's capabilities. A cheaper machine may not provide the precision or features necessary for high-performance applications. Another mistake is selecting a machine that cannot accommodate the specific size or material of the valve being ground. To avoid these mistakes, carefully assess the valve grinding requirements and choose a machine that aligns with the needs of the operation.

Valve grinding machines have become indispensable in modern manufacturing, especially in industries that require high-performance valves. These machines ensure precise valve grinding, improving sealing, reducing wear, and extending valve life. With advancements in technology, they meet the increasing demand for precision. Companies like Suzhou Jianuohao International Trade Co., Ltd. offer high-quality valve grinding machines that enhance performance, reliability, and efficiency, ultimately reducing maintenance costs and downtime.

A: Valve grinding machines are used to grind valve surfaces to precise specifications, ensuring optimal sealing and extending the lifespan of valves in high-performance systems.

A: Valve grinding machines ensure that the valve and seat surfaces are smooth and perfectly shaped, preventing leaks, reducing wear, and improving overall system efficiency.

A: With increasing precision demands, valve grinding machines are crucial for maintaining high-performance valve systems in industries like automotive, aerospace, and oil & gas.

A: Consider valve size, material, required precision, and machine features like speed control and adjustable grinding parameters when selecting a valve grinding machine.

A: Modern valve grinding machines use automation and enhanced grinding methods, improving precision, reducing downtime, and ensuring consistent valve performance in demanding industries.