T: +86-512-66294696

E: sales@tzjmachine.com

E: sales@tzjmachine.com

Add: No.20, Guangdian Road, Guangfu Town, Wuzhong District, Suzhou, China

Views: 0 Author: Site Editor Publish Time: 2025-09-16 Origin: Site

Valve grinding is essential for engine and machinery maintenance. Without precise grinding, valves may not seat properly, leading to leaks and performance issues.

In this article, we'll explore how to use a valve grinding machine, focusing on CNC valve grinding techniques. You'll learn effective methods and key safety tips to get the best results.

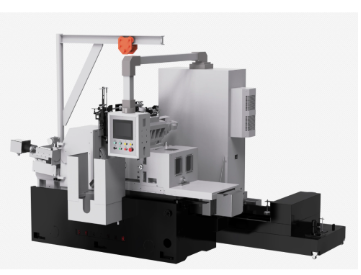

CNC valve grinding machines use computer software to control the grinding process, allowing for the automated movement of the grinding wheel and valve positioning. This provides precision that manual operations simply can't match. These machines are particularly useful for high-volume and complex valve types, where consistency and fine-tuning are required.

Tip: CNC valve grinding machines are perfect for industries that need to grind multiple valve types with varying sizes and materials, improving both efficiency and accuracy.

Before using any valve grinding machine, it's crucial to prepare the machine and valve to ensure safety and optimal performance.

Ensure that the CNC valve grinding machine is set up correctly. This includes checking all components, such as the grinding wheel, chuck, and coolant system. Make sure that the chuck is securely fastened and properly aligned to avoid any wobbling that could lead to inaccuracies during the grinding process.

Different types of valves and materials require specific grinding wheels. Ensure that the grinding wheel selected is compatible with the valve material, whether it's steel, titanium, or any other material. The wrong wheel can damage the valve or cause subpar finishes.

Tip: Always use high-quality grinding wheels for better performance and longer machine life.

Proper valve positioning is essential for achieving the right seat and sealing. CNC machines make this step easier by automating the positioning, but if you're using manual machines, ensure that the valve is properly centered in the chuck, with the valve face aligned to the grinding wheel.

Grinding a valve involves precise steps that require attention to detail. Here, we will break down the step-by-step process of how to use a valve grinding machine effectively.

Turn on the CNC valve grinding machine and wait for it to reach the appropriate speed. Position the valve into the chuck, ensuring that it is secure. For manual grinders, carefully adjust the valve until it is positioned at the right angle for grinding.

Once the valve is securely in place, adjust the grinding wheel to the correct depth. For CNC machines, this can often be done automatically through the software. However, on manual machines, it is necessary to make the adjustment by hand.

Begin the grinding process by activating the machine. The CNC system will move the valve and grinding wheel in a controlled manner, grinding the valve face to achieve the correct angle and finish. Monitor the progress closely, especially if you're using a manual machine, to ensure the process is smooth.

Tip: Always start with a coarse grit wheel for heavy material removal, then switch to finer grits for achieving a smooth finish.

After grinding, inspect the valve to ensure that it's correctly ground and aligned. CNC machines can provide precise measurements and even adjust automatically, but it's still a good practice to inspect the work visually or using a micrometer.

Operating a valve grinding machine requires adherence to safety procedures. Improper use can lead to accidents, equipment damage, or poor valve performance.

Before starting, ensure that you're wearing protective gear, such as goggles, gloves, and hearing protection. Grinding machines create a significant amount of dust and noise, so personal protection is essential for health and safety.

Keep the machine well-maintained. Regularly check the coolant system, grind wheels, and chuck to ensure they are in good working condition. A poorly maintained machine can lead to inaccuracies or even machine failure.

Stay attentive during the grinding process. The operator should monitor the machine's behavior, listen for unusual noises, and watch for excessive vibrations. If anything seems off, stop the machine immediately and investigate.

Tip: If using CNC valve grinding machines, ensure that you regularly calibrate the machine to prevent errors in precision over time.

Despite the best precautions, valve grinding machines may sometimes face issues that can affect the quality of the final product. Here are some common problems you may encounter:

If the finish is rough or inconsistent, it could be due to a number of factors. Check the grinding wheel for wear or improper grit selection. Another possible cause is incorrect valve positioning or chuck misalignment.

Uneven grinding may occur if the machine isn't level or if the valve is not properly centered. In CNC systems, ensure that the program is set correctly and the machine is calibrated. For manual systems, check the alignment frequently during grinding.

Excessive heat can be generated during grinding, which can lead to thermal damage on the valve. Ensure that the coolant system is working correctly to prevent overheating. Use the right pressure and flow rate for the coolant to maintain proper lubrication and cooling.

Tip: Always inspect valves for heat discoloration or surface cracks after grinding to ensure no damage was caused during the process.

Learning how to use a valve grinding machine efficiently and safely is key to ensuring high-quality valve seats. CNC valve grinding machines offer precision and consistency, essential for modern industrial operations. By following the correct setup, grinding, and safety steps, you can achieve optimal results and extend the lifespan of both your valves and equipment.

CNC valve grinding machines from Tianzhijiao Machinery provide excellent precision and value in valve maintenance, offering long-lasting performance for various industries.

A: A valve grinding machine is a tool used to grind and restore the sealing surfaces of valves, ensuring proper fit and performance. CNC Valve Grinding machines offer enhanced precision and automated control for efficient operation.

A: To use a valve grinding machine safely, ensure proper setup, use the right safety gear, and follow machine instructions. Regularly maintain the equipment and follow guidelines for CNC Valve Grinding to minimize risks.

A: CNC Valve Grinding machines provide greater precision, repeatability, and consistency. This automated approach reduces human error and increases efficiency, making it ideal for industries requiring high-quality valve seating.