T: +86-512-66294696

E: sales@tzjmachine.com

E: sales@tzjmachine.com

Add: No.20, Guangdian Road, Guangfu Town, Wuzhong District, Suzhou, China

Views: 0 Author: Site Editor Publish Time: 2025-12-05 Origin: Site

In the fast-paced world of manufacturing, precision and efficiency are crucial. High-volume production demands machines that can meet these needs without compromising on quality. This is where Groove Centerless Grinding Machines come into play.

These machines are reshaping high-volume production by enhancing speed, accuracy, and cost-efficiency. In this article, we will explore how Groove Centerless Grinding Machines are revolutionizing the manufacturing industry, especially in sectors like automotive, aerospace, and medical devices.

Groove Centerless Grinding Machines function by holding the workpiece between two rotating wheels: a grinding wheel and a regulating wheel. The workpiece is supported by a blade or work rest, which keeps it in place while the grinding wheel removes material. Unlike traditional grinding methods, which require the workpiece to be held at two points (like centers), the centerless design eliminates the need for these holding points, allowing for continuous and uninterrupted grinding.

This design makes groove centerless grinding machines perfect for high-volume production where consistent quality and speed are paramount. The machines are capable of working with a variety of materials and can maintain precise tolerances without requiring constant adjustments, which is essential when working at scale.

One of the key reasons groove centerless grinding machines excel in high-volume production is their automation capabilities. Unlike traditional methods, these machines often integrate advanced automation systems, which can operate without constant supervision. This reduces downtime, lowers labor costs, and speeds up the production process. Additionally, these machines are incredibly versatile. They can handle a wide range of materials, from metals to ceramics, and workpieces of various shapes and sizes, which is critical when dealing with large-scale production runs.

Furthermore, groove centerless grinding machines can produce parts with greater consistency and precision compared to traditional grinding methods. This leads to a reduction in scrap rates and an increase in product yield, two essential factors in any high-volume production environment.

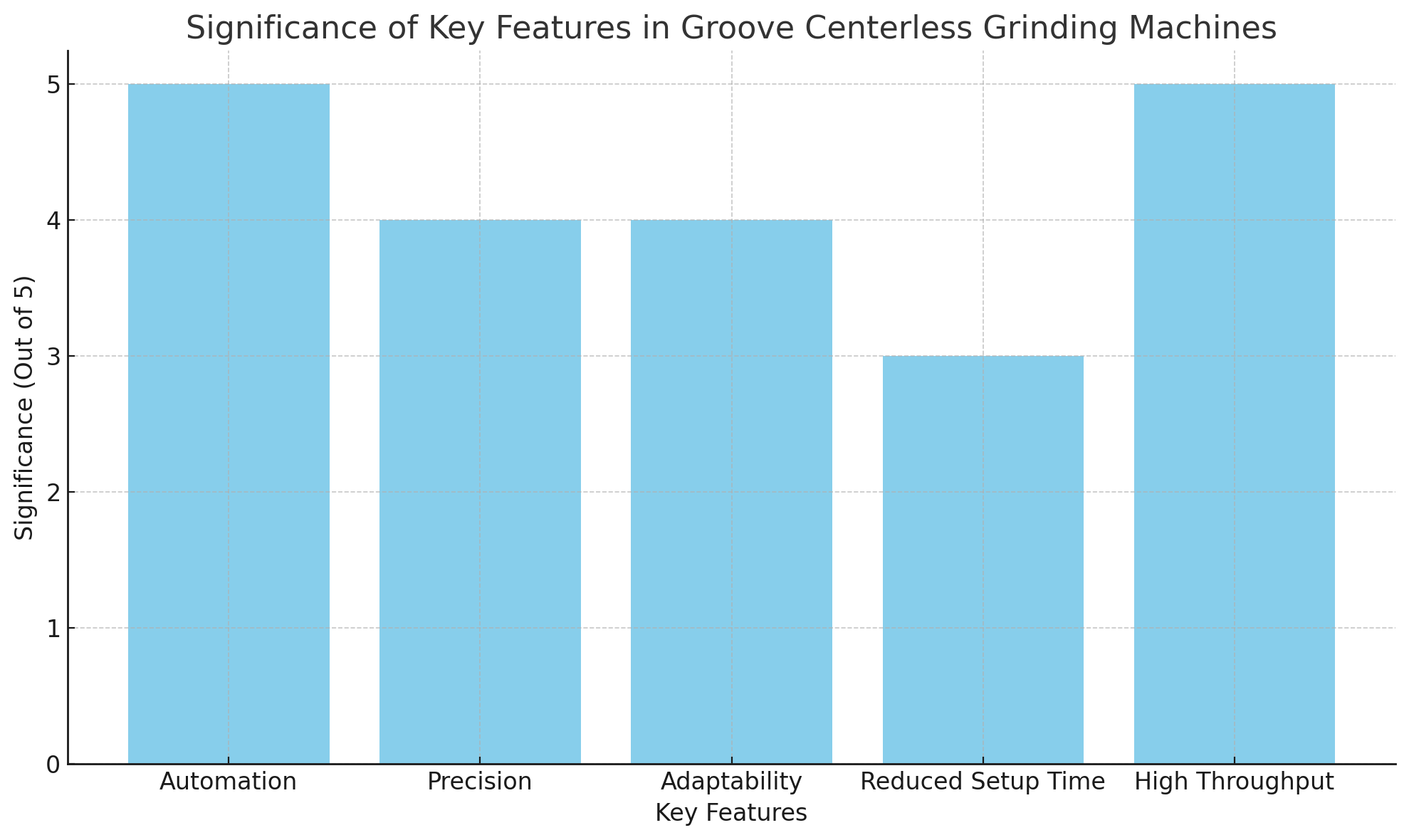

Feature | Advantage |

Automation | Reduces manual intervention, increasing production efficiency. |

Precision | Ensures high precision with tight tolerances in mass production. |

Adaptability | Can handle various workpiece sizes and materials. |

Reduced Setup Time | Minimizes downtime, enhancing overall production flow. |

High Throughput | Capable of processing a large volume of components quickly. |

In high-volume production, precision is critical. Groove centerless grinding machines are designed to achieve tight tolerances in parts, often to the micron level. This level of accuracy is essential for industries like aerospace and automotive, where the slightest error can compromise safety and functionality. These machines are capable of maintaining these tight tolerances across thousands of parts without variation, making them indispensable in environments where consistency is key.

By maintaining such precision at high speeds, groove centerless grinding machines ensure that each part meets the same exacting standards, even during extended production runs. This consistency in quality is one of the driving factors behind their increasing popularity in high-volume industries.

Another key feature of groove centerless grinding machines is their ability to handle complex geometries. These machines can grind parts that have intricate shapes or multiple diameters with ease. In high-volume production, the ability to efficiently grind parts with complex features is vital. Groove centerless grinders excel at processing such components without compromising speed or accuracy.

This flexibility makes them especially useful in the automotive and aerospace industries, where parts like shafts, bearings, and turbine blades require both intricate geometries and tight tolerances.

In high-volume manufacturing, time is of the essence. Groove centerless grinding machines are designed to minimize setup times and allow for continuous operation. These machines can switch between different workpieces with minimal downtime, allowing manufacturers to keep their production lines running smoothly. Additionally, automated systems help eliminate human error, which further improves productivity and reduces the likelihood of costly mistakes.

The ability to reduce setup time while maintaining quality is one of the primary reasons groove centerless grinding machines are ideal for high-volume applications.

In the automotive industry, precision and efficiency are critical. Groove centerless grinding machines are used extensively to produce high-precision parts such as shafts, bearings, and gears. These parts are essential for engine performance, safety features, and transmission systems. Groove centerless grinding machines ensure that these components are produced to exacting standards, reducing the risk of defects that could lead to system failure or safety hazards.

These machines are also capable of handling large volumes of parts, which is essential in the automotive industry’s fast-paced production environment. Their high throughput ensures that manufacturers can meet the ever-increasing demand for automotive components without sacrificing quality.

The aerospace and defense industries require some of the highest levels of precision in manufacturing. Parts such as turbine blades, engine casings, and landing gear must meet stringent safety standards. Groove centerless grinding machines are capable of grinding these critical components with extreme accuracy, ensuring that they can perform reliably in the most demanding conditions.

In addition to precision, the ability to handle complex geometries makes groove centerless grinders invaluable in the production of aerospace parts. The ability to produce these parts at scale, without sacrificing quality, is a major advantage for manufacturers in this sector.

Medical device manufacturers rely on Groove Centerless Grinding Machines for producing components such as orthopedic implants, surgical instruments, and diagnostic equipment. These components must meet strict dimensional tolerances and biocompatibility standards. Groove grinding offers the precision required for such delicate applications, ensuring that the parts function as intended while also meeting safety and regulatory requirements.

The adaptability of groove centerless grinders to a wide range of materials, from stainless steel to advanced ceramics, further expands their use in the medical industry, where precision is non-negotiable.

Industry | Applications of Groove Centerless Grinding Machines |

Automotive | Used for producing automotive parts like shafts, bearings, and engine components. |

Aerospace & Defense | Grinding turbine blades, landing gear, and engine components with precision. |

Medical Devices | Manufacturing high-precision components like surgical tools and implants. |

Electronics | Grinding parts for electronics that require tight tolerances. |

One of the biggest advancements in groove centerless grinding technology is the integration of automation and Industry 4.0 principles. Modern groove grinding machines often feature CNC (computer numerical control) systems, allowing for automated adjustments during the grinding process. This increases the machine's precision and reduces human error. Additionally, many machines are now equipped with sensors and real-time monitoring systems that provide feedback on the grinding process. This data can be used to optimize the machine's performance and detect any issues before they cause a failure, reducing downtime.

Recent advancements in grinding wheel materials have made groove centerless grinding machines even more efficient. The development of superabrasive materials, such as cubic boron nitride (CBN) and diamond-coated wheels, has significantly increased the performance and lifespan of grinding wheels. These new materials are more durable and wear-resistant, allowing manufacturers to produce parts faster and with greater precision.

Sustainability is a growing concern in manufacturing, and groove centerless grinding machines are rising to the challenge. Many of the latest machines are designed with energy-efficient motors and cooling systems that minimize waste and reduce power consumption. Additionally, newer machines incorporate features like coolant filtration systems, which not only reduce energy use but also extend the life of the grinding wheels.

These energy-efficient innovations make groove centerless grinding machines a more sustainable choice for manufacturers, helping them reduce their environmental impact while maintaining high productivity.

Innovation | Impact on Groove Centerless Grinding Machines |

CNC Technology | Enables precise control, automation, and real-time monitoring of the grinding process. |

IoT Integration | Allows for predictive maintenance and better machine performance monitoring. |

Advanced Grinding Wheels | Use of CBN and diamond-coated wheels increases durability and cutting performance. |

Energy-Efficient Motors | Reduces energy consumption, aligning with sustainability goals in manufacturing. |

While the upfront cost of Groove Centerless Grinding Machines can be substantial, they offer significant long-term savings. The high precision and efficiency of these machines mean that manufacturers can reduce scrap rates, lower operational costs, and increase product yield. Furthermore, the automation capabilities of these machines reduce labor costs, as they require fewer operators to run them efficiently.

The combination of reduced material waste, improved productivity, and lower labor costs makes the investment in groove centerless grinding machines a wise long-term choice for high-volume production.

Like any piece of industrial machinery, groove centerless grinding machines require regular maintenance to operate at peak efficiency. Scheduled maintenance programs, including the replacement of grinding wheels and routine machine inspections, help prevent downtime and ensure the machine's longevity. By proactively maintaining these machines, manufacturers can avoid costly repairs and keep their production lines running smoothly.

Aspect | Initial Investment | Long-Term Savings |

Machine Cost | High upfront cost | Reduced labor costs due to automation. |

Energy Consumption | Higher energy usage initially | Lower energy consumption with modern machines. |

Maintenance | Regular servicing required | Less downtime and extended machine lifespan. |

Material Wastage | Potential for some scrap | Less material waste with optimized grinding. |

The future of Groove Centerless Grinding Machines looks promising, with ongoing advancements in automation, artificial intelligence (AI), and machine learning. These technologies will further enhance the precision and speed of grinding processes. For instance, AI could be used to predict maintenance needs, optimize grinding parameters in real-time, and identify potential issues before they arise. This shift towards smarter, more adaptive machines will play a crucial role in the continued evolution of high-volume manufacturing.

As industries around the world demand greater precision, the need for advanced grinding technologies will only increase. The continued push for smaller, more complex components, particularly in automotive, aerospace, and medical devices, will drive the demand for Groove Centerless Grinding Machines. Their ability to deliver high throughput with unparalleled accuracy makes them the perfect solution for meeting these evolving manufacturing requirements.

Groove centerless grinding machines are revolutionizing high-volume production with unmatched precision, automation, and adaptability. They are transforming industries like automotive, aerospace, and medical devices, meeting the demand for high-precision components at scale. Suzhou Jianuohao International Trade Co., Ltd. is leading this innovation, offering advanced machines that help manufacturers achieve top-quality, efficient, and sustainable production processes.

A: A Groove Centerless Grinding Machine is a specialized machine designed for high-precision grinding of cylindrical components without the need for centers. It uses a regulating wheel and abrasive wheel to achieve high-volume, precise manufacturing.

A: These machines enhance production efficiency by automating processes, minimizing setup times, and allowing for continuous grinding of multiple workpieces with consistent precision.

A: Industries such as automotive, aerospace, and medical devices benefit significantly from groove centerless grinding machines due to their ability to produce high-precision components at scale.

A: They provide tight tolerances, high throughput, and minimal downtime, making them crucial for meeting the demands of modern manufacturing, especially in high-volume production.

A: While the initial investment can be high, the long-term savings from reduced labor costs, increased throughput, and minimized scrap make them a cost-effective solution for high-volume production.