T: +86-512-66294696

E: sales@tzjmachine.com

E: sales@tzjmachine.com

Add: No.20, Guangdian Road, Guangfu Town, Wuzhong District, Suzhou, China

Views: 0 Author: Site Editor Publish Time: 2025-09-15 Origin: Site

CNC grinding is a critical process in modern manufacturing. It helps achieve high precision in mechanical parts, especially in valve components. But how does it work, and why is it so important?

In this article, we will explore the fundamentals of CNC grinding. You'll learn about the process, its applications, and the importance of CNC valve grinding in achieving optimal results.

CNC grinding refers to the use of computer-controlled machines (CNC machines) to perform grinding operations with high precision. These machines use grinding wheels to remove material from the surface of a workpiece, providing smooth finishes and accurate shapes.

The CNC grinding process is widely used in manufacturing for parts like valves, gears, bearings, and more. Unlike manual grinding, CNC grinding is automated, making it faster and more precise. The process is especially important when dealing with tight tolerances or complex shapes.

Key Features of CNC Grinding:

Automation: Controlled by CNC software, allowing for high precision and repeatability.

Precision: Achieves tight tolerances, ideal for industries where accuracy is critical.

Consistency: Every part produced is identical, making it perfect for mass production.

There are several types of CNC grinding, each suited to different applications:

Surface grinding involves using a rotating grinding wheel to remove material from the surface of a workpiece, making it flat and smooth. This method is commonly used to achieve a polished finish and precise dimensions.

In cylindrical grinding, the workpiece is rotated while a grinding wheel moves along the length of the part. This is ideal for producing cylindrical shapes with a high degree of precision.

This process involves grinding the inside diameter of a cylindrical part. It is often used for making parts with small, intricate holes or internal geometries, such as valve seats.

CNC valve grinding is a specialized process used to precisely grind the surfaces of valve components. In industries like automotive and aerospace, valves must be ground to exact specifications to ensure optimal performance and durability. CNC valve grinding machines are capable of producing valves with very tight tolerances, making them essential in high-performance engines.

Ensure the CNC valve grinding machine you choose has the right specifications for your industry's demands. Higher precision machines are crucial for industries like aerospace and automotive, where every micron counts.

The CNC grinding process can be broken down into several stages, each essential for achieving the desired result. Here's a step-by-step explanation of the process:

Before the grinding process begins, the workpiece is set up on the machine. In CNC valve grinding, the valve or valve component is securely mounted on a fixture that holds it in place during grinding. This step is crucial for ensuring the part remains stable during the process.

Once the workpiece is in place, the CNC machine operator inputs the necessary parameters, including speed, feed rate, and depth of cut. For CNC valve grinding, precise control of these parameters is essential to prevent damage to the valve and to ensure an even finish.

The grinding wheel, typically made from abrasive materials like diamond or cubic boron nitride, rotates at high speeds. The wheel makes contact with the workpiece and removes material to achieve the desired shape or finish. In CNC grinding, this process is controlled by a computer, allowing for the creation of complex shapes and smooth surfaces.

After the main grinding operation, the part may undergo additional finishing processes, such as polishing, to improve surface quality or to achieve a specific texture.

Key Factors in CNC Grinding:

Material Selection: The type of material being ground determines the type of grinding wheel and process used.

Tool Wear: The grinding wheel wears down over time, which may require regular maintenance or replacement.

Temperature Control: Grinding generates heat, and managing this heat is essential for maintaining part integrity.

There are numerous benefits to using CNC grinding over traditional manual grinding, including:

Higher Precision: CNC grinding machines provide greater accuracy and repeatability, making them ideal for high-precision parts like valve components.

Increased Efficiency: Automated processes reduce the need for manual labor, cutting down on production time and costs.

Complex Shapes: CNC grinding can create intricate designs and shapes that would be impossible to achieve with manual methods.

Reduced Errors: Since the process is computer-controlled, human error is minimized, leading to fewer defects.

In manual grinding, operators control the grinding wheel and the workpiece by hand. While this allows for flexibility, it often results in inconsistent results. CNC grinding, however, eliminates human error and guarantees precision across large production runs.

Surface grinding is a specific type of CNC grinding used to create smooth, flat surfaces. CNC grinding encompasses many processes, including cylindrical, internal, and surface grinding, while surface grinding is just one of these specialized techniques.

Polishing is a secondary process used to enhance the surface finish. It typically follows grinding to achieve a smoother, more reflective surface. CNC grinding, on the other hand, focuses on removing material to create precise shapes and sizes.

CNC grinding is used in various industries, including:

Automotive: CNC valve grinding plays a crucial role in engine performance, ensuring valve components meet exact specifications.

Aerospace: Components like turbine blades and precision bearings are often ground using CNC machines for maximum performance and reliability.

Medical Devices: CNC grinding is used to create high-precision parts such as surgical tools and implants.

Tool Manufacturing: CNC machines grind tools and dies to create accurate cutting surfaces for use in other manufacturing processes.

Regular maintenance of CNC grinding machines is crucial to ensure their longevity and optimal performance. Here are some tips for keeping your machines in top condition:

Regular Cleaning: Dust and debris can affect machine performance. Regularly clean the machine to prevent buildup.

Check Tool Wear: Grinding wheels wear out over time, so it’s important to regularly inspect and replace them when necessary.

Lubrication: Proper lubrication reduces friction and prevents wear on the machine’s moving parts.

Calibration: Periodically calibrate the machine to ensure it maintains the correct tolerances.

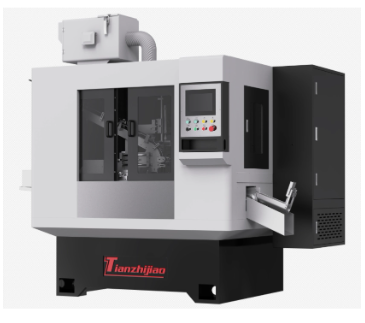

CNC grinding is essential for achieving precision and efficiency in modern manufacturing. From CNC valve grinding to other specialized techniques, understanding the process improves operations. It enhances product quality, reduces costs, and ensures competitiveness. Businesses can benefit from investing in CNC grinding machines and adopting best maintenance practices. Tianzhijiao Machinery offers high-quality machines to support your operations.

A: CNC grinding is a precise machining process used for shaping and finishing materials. It utilizes a CNC-controlled grinding machine to achieve highly accurate results in various industries.

A: CNC valve grinding involves using CNC machines to precisely grind valve surfaces. This process ensures a perfect fit, improving valve performance and extending service life.

A: CNC grinding enhances accuracy, reduces errors, and improves overall efficiency. It is crucial for producing high-quality parts with tight tolerances in industries like automotive and aerospace.