T: +86-512-66294696

E: sales@tzjmachine.com

E: sales@tzjmachine.com

Add: No.20, Guangdian Road, Guangfu Town, Wuzhong District, Suzhou, China

Views: 0 Author: Site Editor Publish Time: 2025-10-17 Origin: Site

Ever wondered how industries achieve high-volume production with precision? Enter the Double Station Electrical Upsetting Machine. This advanced equipment revolutionizes manufacturing by doubling productivity without extra space. In this post, you'll learn what this machine is and its vital role in modern manufacturing.

The Double Station Electrical Upsetting Machine stands out by featuring two operational stations. This design allows simultaneous forging of two rod components, effectively doubling the output compared to single-station machines. By processing two parts at once, manufacturers can significantly boost productivity without needing extra floor space or additional machines. This setup is ideal for industries requiring high-volume production of engine valve rods and similar components, ensuring faster turnaround and improved workflow efficiency.

Durability is crucial in forging equipment. This machine boasts a robust steel plate welded structure, providing a solid and stable frame. The structure undergoes precision machining on the working face using large-scale machine tools, guaranteeing assembly accuracy and long-term reliability. This sturdy build minimizes vibrations and mechanical wear during operation, which helps maintain consistent forging quality and extends the machine's service life. The strength of the welded steel also supports the heavy forces involved in upsetting processes, ensuring safety and performance stability.

The machine integrates advanced hydraulic and heating systems to deliver precise and efficient forging. The hydraulic system operates under medium pressure, powered by a motor-driven vane pump, and uses proportional pressure regulators for fine control. This setup ensures smooth, balanced force application during upsetting, reducing cycle times and improving product consistency.

Heating is managed by two 30 KVA single-phase transformers controlled by SCR voltage regulators. This allows stepless voltage adjustment, providing constant current heating for uniform material temperature. The heating system's precision prevents overheating and material defects, essential for quality forging. Additionally, a cooling system maintains optimal temperatures for the anvil electrode, clamping electrode, and hydraulic oil, protecting components from thermal stress and ensuring continuous operation.

Together, these systems provide the machine with the power, control, and thermal management needed for high-quality forging of rod components.

The Double Station Electrical Upsetting Machine delivers a powerful forging force of up to 190 kN, enabling it to handle tough metal deformation tasks effectively. This force is applied through a forging cylinder that has a maximum stroke length of 600 mm, allowing for deep and precise upsetting operations. The anvil cylinder supports a maximum stroke of 300 mm, providing balanced pressure during the forging process. Meanwhile, the clamping cylinder offers a stroke of up to 50 mm, ensuring secure holding of the workpiece throughout the operation. These adjustable stroke settings give operators flexibility to tailor the machine's performance to various rod sizes and shapes.

This machine is designed to work with rod diameters ranging from 16 to 26 mm, accommodating a wide range of component sizes commonly used in engine valves and other rod-based parts. It can process rods up to 800 mm in length, making it suitable for both short and long components. These capabilities enable manufacturers to use the machine for diverse production needs without frequent tooling changes, improving overall efficiency.

Heating is a critical part of the upsetting process, and this machine uses two 30 kVA single-phase transformers for power. The transformers are controlled by SCR voltage regulators, allowing stepless adjustment of the primary voltage. This precise control ensures uniform heating of the rod, preventing defects caused by uneven temperature distribution. The heating system maintains a constant current, which is essential for consistent material properties during forging.

To protect the machine and maintain optimal operating conditions, a dedicated cooling system manages the temperature of the anvil electrode, clamping electrode, and hydraulic oil. Water cooling at a pressure of 3 to 3.5 bar ensures components stay within safe temperature limits, preventing overheating and extending the life of critical parts.

| Parameter | Specification | Unit |

|---|---|---|

| Max. Hydraulic Working Pressure | 16 | MPa |

| Max. Forging Force | 190 | kN |

| Max. Stroke of Forging Cylinder | 600 | mm |

| Max. Stroke of Anvil Cylinder | 300 | mm |

| Max. Stroke of Clamping Cylinder | 50 | mm |

| Rod Diameter | 16-26 | mm |

| Rod Length | 800 | mm |

| Heating Power | 70 (2 sets) | kVA |

| Primary Voltage | 380 | V |

| Frequency | 50 | Hz |

| Oil Pump Specification | YB1-40 | |

| Oil Pressure | 10 | MPa |

| Oil Flow | 40 | mL/r |

| Motor Power | 11 | kW |

| Motor Speed | 960 | RPM |

These specifications highlight the machine’s capability to deliver consistent, high-quality forging for a variety of rod components.

Tip: Regularly monitor the forging cylinder stroke and heating voltage settings to optimize forging quality and prevent material defects during production.

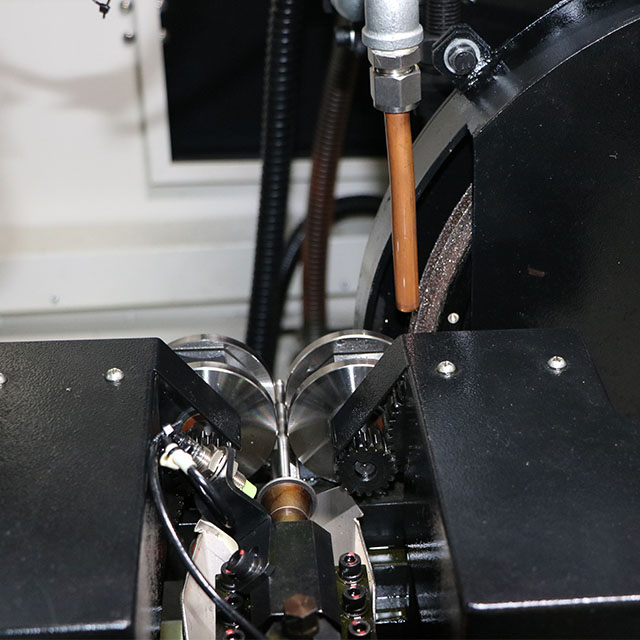

The anvil system plays a crucial role in the Double Station Electrical Upsetting Machine. It includes the anvil cylinder, guide block mechanism, anvil electrode, anvil seat, and alloy conductive block. The guide block is mounted on two round guide columns, which undergo heat treatment to boost strength and extend service life. When forging, the anvil cylinder pushes the guide block, ensuring balanced force application. The anvil electrode, made of T2 electrolytic copper, is installed on the guide block on one side and connected to the transformer on the other. The anvil seat and alloy conductive block connect with the anvil electrode, with the alloy block acting as a wear-resistant part.

The clamping system consists of the clamping cylinder, clamping electrode, and jaw conductive block. It securely holds the workpiece during forging, preventing movement or bending. To improve stability, auxiliary supports are added to prevent bending during operation. This system ensures the rod stays firmly in place, which is vital for accurate and consistent upsetting.

The upsetting cylinder drives the guide block mechanism, which moves to apply forging pressure. This cylinder uses a double oil circuit design, reducing return time and improving efficiency. The guide block mechanism ensures smooth, precise movement to shape the rod accurately. The combination of hydraulic power and mechanical guidance guarantees consistent force distribution, reducing wear and increasing the machine's lifespan.

The machine’s hydraulic system operates on a medium-pressure oil circuit, supplied by a motor-driven vane pump. Hydraulic valves are mounted on an integrated oil block and use proportional regulators to control pressure finely. This setup delivers smooth, balanced force during forging, enhancing product quality and reducing cycle time.

The electrical system features Mitsubishi PLC controls, a touch screen interface, and a servo control system. These components allow precise parameter settings, such as forging stroke length and heating voltage. The upsetting cylinder stroke is monitored by an encoder for accurate positioning. Operators can select adjustment modes including semi-automatic and automatic operation, making the machine user-friendly and flexible.

The heating system uses two 30 KVA single-phase transformers with SCR voltage regulators for stepless voltage adjustment. This ensures constant current heating, providing uniform rod temperature and preventing overheating. A dedicated cooling system manages the temperature of the anvil electrode, clamping electrode, and hydraulic oil using water at 3 to 3.5 bar pressure. This cooling protects components from thermal stress and maintains stable operation.

The Double Station Electrical Upsetting Machine is widely used in forging engine valves, a critical component in automotive and industrial engines. It efficiently shapes valve stems by applying precise upsetting force and controlled heating. The dual-station design allows two valve rods to be forged simultaneously, doubling output without extra equipment. This capability helps meet high production demands while maintaining consistent quality. The machine’s accuracy ensures valve stems fit perfectly in engines, improving performance and durability.

Beyond engine valves, this machine excels in producing various rod components. It handles rods ranging from 16 to 26 mm in diameter and up to 800 mm long. Manufacturers use it to forge parts like fasteners, bolts, and specialized metal rods. The precise hydraulic and heating systems ensure uniform material properties, critical for parts subjected to mechanical stress. Its robust structure supports heavy-duty forging, making it suitable for large batch production runs. The ability to adjust forging strokes and heating voltage allows customization for different rod types.

Several industries rely on the Double Station Electrical Upsetting Machine for their manufacturing needs:

Automotive: Engine valve rods, connecting rods, and other critical components.

Aerospace: Precision rod forging for aircraft parts requiring high strength.

Machinery Manufacturing: Production of durable fasteners and structural rods.

Construction: Forging rods used in heavy machinery and equipment.

Agricultural Equipment: Manufacturing robust rods for farming tools and machines.

Its versatility and high productivity make it a valuable asset across these sectors, helping manufacturers improve efficiency and product consistency.

The Double Station Electrical Upsetting Machine offers a significant leap in efficiency compared to traditional single-station machines. By operating two stations simultaneously, it doubles the production capacity without increasing the machine footprint. This means manufacturers can produce more parts in less time while saving valuable floor space. The integration of precise hydraulic controls and servo-driven mechanisms ensures consistent force application, leading to highly accurate forging results. This precision minimizes material waste and reduces the need for secondary machining, ultimately saving costs.

Traditional upsetting machines require sequential processing, handling one rod at a time. The dual-station design allows two rods to be forged concurrently, cutting cycle times dramatically. The machine’s advanced hydraulic system, featuring proportional pressure regulators, delivers smooth, balanced force that speeds up the upsetting process without sacrificing quality. Additionally, the rapid return of the upsetting cylinder, enabled by the double oil circuit design, shortens downtime between cycles. These factors combine to enhance throughput and meet high-volume production demands efficiently.

Maintaining consistent quality is critical in forging operations. This machine’s robust steel plate welded structure provides a stable foundation that reduces vibration and mechanical wear. The precise control of heating via SCR voltage regulators ensures uniform rod temperature, preventing defects caused by uneven heating. The cooling system protects key components from thermal stress, extending machine life and reducing maintenance frequency. Together, these features deliver reliable, repeatable performance, making the Double Station Electrical Upsetting Machine a trusted choice for demanding manufacturing environments.

Maintaining your Double Station Electrical Upsetting Machine regularly ensures it runs smoothly and lasts longer. Start by inspecting hydraulic oil levels and quality; change the oil as recommended by the manufacturer to avoid contamination that can damage components. Check all hydraulic hoses and connections for leaks or wear and replace any faulty parts immediately. Clean the cooling system filters and ensure water pressure stays within the 3 to 3.5 bar range to prevent overheating of the anvil electrode, clamping electrode, and hydraulic oil.

Inspect the electrical system, including transformers and SCR voltage regulators, for any signs of wear or damage. Tighten loose connections and test the control panel and sensors to ensure proper operation. Lubricate guide columns, bearings, and moving parts regularly to reduce friction and wear. Also, examine the anvil and clamping electrodes for wear and replace the alloy conductive blocks if they show signs of excessive wear, as these parts are critical for maintaining forging accuracy.

Operate the machine according to the manufacturer’s guidelines to maximize efficiency and safety. Always preheat the rods to the recommended temperature before forging to avoid material defects. Use the machine’s control system to set the correct forging stroke and heating voltage for each batch, ensuring consistent quality. Avoid overloading the machine beyond its specified rod diameter and length limits (16-26 mm diameter, up to 800 mm length) to prevent mechanical strain.

Train operators thoroughly on the use of the Mitsubishi PLC system, touch screen interface, and servo control to enable smooth adjustments during production. Employ semi-automatic or automatic operation modes depending on production needs to optimize cycle times. Always secure the workpiece firmly using the clamping system and verify the anti-bending supports are correctly positioned to prevent deformation during forging.

If the machine experiences inconsistent forging force or stroke irregularities, first check hydraulic pressure and valve settings. Low oil pressure or dirty filters often cause these issues. For heating problems like uneven rod temperature or failure to reach target heat, inspect the transformers and SCR regulators for faults or connection problems. Cooling system failures may lead to overheating; ensure water flow and pressure are adequate and cooling channels are clear.

Unusual noises or vibrations often indicate misaligned guide blocks or worn bearings. Regularly check guide block alignment and replace worn parts promptly. If the machine’s control system shows error codes or malfunctions, perform a system reset and verify sensor connections. Consult the user manual for specific error troubleshooting or contact technical support if problems persist.

The Double Station Electrical Upsetting Machine enhances productivity with its dual operational stations, advanced hydraulic and heating systems, and robust construction. It efficiently forges rod components, meeting high-volume demands in industries like automotive and aerospace. With precise control and consistent quality, it reduces production time and costs. As manufacturing evolves, this machine offers promising prospects for increased efficiency and reliability. Jianuohao's innovative design ensures the machine's value in diverse manufacturing environments, providing a competitive edge in forging operations.

A: A Double Station Electrical Upsetting Machine is a forging device with two operational stations, enabling simultaneous processing of two rod components, enhancing productivity and efficiency.

A: It features two operational stations, doubling output by processing two parts simultaneously, ideal for high-volume production without extra floor space.

A: It offers enhanced efficiency, precision, and reduced production time, doubling capacity without increasing space, with consistent quality through advanced controls.

A: Benefits include increased productivity, precise control of forging and heating, reduced cycle times, and consistent quality with minimal material waste.

A: Check hydraulic pressure, valve settings, and cooling systems for irregularities. Inspect transformers and SCR regulators for heating issues, and realign guide blocks for unusual vibrations.