T: +86-512-66294696

E: sales@tzjmachine.com

E: sales@tzjmachine.com

Add: No.20, Guangdian Road, Guangfu Town, Wuzhong District, Suzhou, China

Views: 0 Author: Site Editor Publish Time: 2025-11-22 Origin: Site

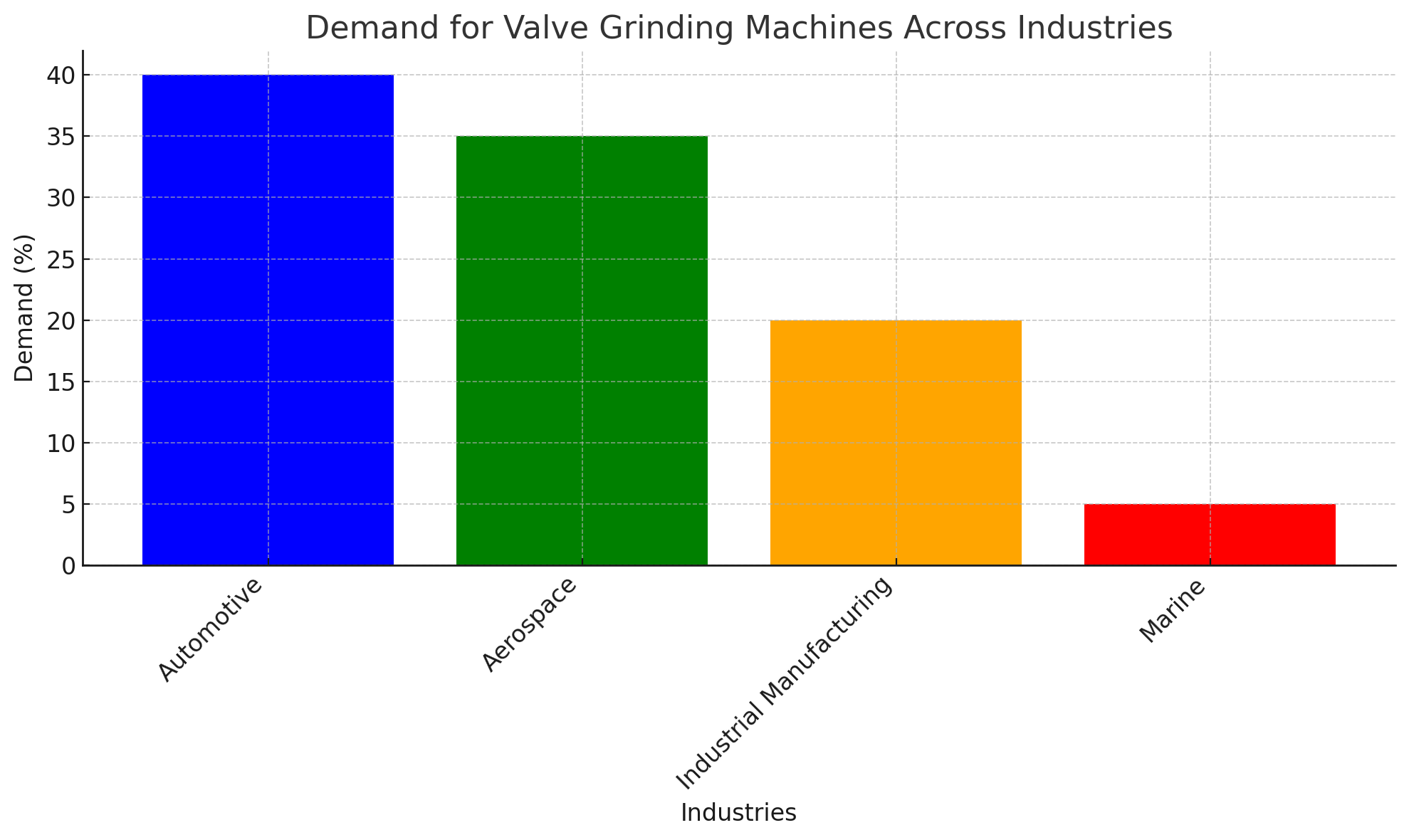

In recent years, the demand for advanced valve grinding machines has surged across various industrial sectors. These machines are critical for ensuring the precision and longevity of valve systems, which are essential for high-performance operations.

This article explores the growing need for valve grinding machines, their role in boosting efficiency, and the technological advancements driving their evolution. You'll learn how these machines impact industries like automotive, aerospace, and manufacturing.

The industrial landscape is evolving towards higher precision in manufacturing, driven by the need for more complex and reliable components. Valve grinding machines are crucial in achieving these precision standards, especially in industries where small imperfections can lead to significant performance issues. The demand for precision components, including valves, has surged as industries push for higher efficiency, tighter tolerances, and more durable products. Valve grinding machines enable manufacturers to meet these demands by ensuring valves are ground to exact specifications, resulting in better sealing, extended lifespan, and reduced maintenance costs.

In sectors such as automotive, aerospace, and industrial machinery, operational efficiency is a top priority. Valve grinding machines contribute significantly by minimizing downtime and enhancing productivity. In high-volume manufacturing environments, efficient machinery is essential to maintain production schedules and avoid costly disruptions. The ability of valve grinders to quickly restore valves to optimal conditions ensures that critical systems function without interruption. As industries increasingly focus on reducing downtime, the importance of advanced valve grinding machines in maintaining equipment functionality and reliability cannot be overstated.

Preventive maintenance has become a key strategy for industries aiming to extend the lifespan of their machinery while minimizing unexpected repairs. Valve grinding machines play an integral role in this approach, helping to restore worn-out valves and prevent further damage to critical systems. By regularly maintaining valve surfaces, industries can avoid costly replacements and ensure their equipment remains in top condition. As more companies prioritize preventive maintenance to reduce unplanned outages, the demand for valve grinding machines continues to grow.

The automotive industry’s increasing focus on fuel efficiency and performance is fueling the demand for high-precision valve grinding. Modern engines, particularly those in electric and hybrid vehicles, require valves to operate with extremely tight tolerances. Valve grinding machines are used to ensure that engine valves are ground precisely to meet stringent performance and emissions standards. As automotive technologies continue to evolve, the need for advanced valve grinding techniques will only intensify, ensuring optimal engine performance and longevity.

The aerospace sector demands the highest levels of precision for its critical components, where any failure could lead to catastrophic consequences. Valve grinding machines are indispensable in maintaining the reliability and functionality of components in aircraft engines and other aerospace systems. The need for consistent, precise valve grinding ensures that aircraft operate safely, efficiently, and within regulatory standards. As the aerospace industry expands, especially with the increasing demand for air travel, the reliance on precision equipment like valve grinders will continue to grow.

In industrial manufacturing, the role of valve grinding machines is essential for ensuring the smooth operation of equipment. These machines help keep valves in top condition, allowing production lines and machinery to run efficiently. Whether in power plants, chemical plants, or heavy manufacturing facilities, valve grinders play a critical role in maintaining the reliability of valve systems. The increasing automation of industrial processes also drives the demand for advanced grinding machines, which are crucial for maintaining automated equipment’s optimal performance.

The marine industry is another significant driver of valve grinding machine demand. Marine engines must withstand harsh environmental conditions, requiring frequent maintenance to keep them running efficiently. Valve grinding machines help maintain the seals and functions of valves in large marine engines, ensuring their continued performance. As global trade grows and the demand for shipping increases, the role of valve grinding machines in the marine industry will continue to be vital in reducing downtime and ensuring engine reliability.

Industry | Specific Demand | Key Application |

Automotive | High-precision engine components | Precision grinding for engine valves and components like camshafts, valve stems |

Aerospace | Precision for critical engine and aircraft components | Grinding for turbine blades, engine valves, landing gears |

Industrial Manufacturing | Maintaining manufacturing equipment | Valve grinders ensure efficiency in machinery maintenance |

Marine | Maintenance of marine engine valves | Grinding to ensure performance and durability of marine engines |

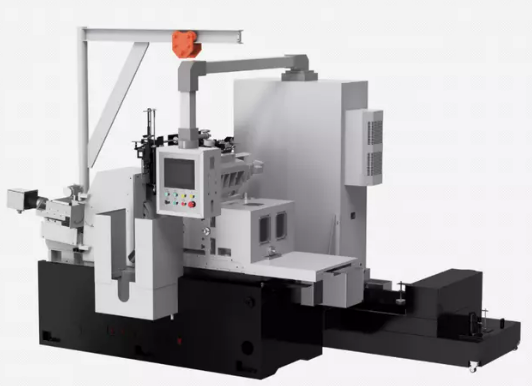

Automation and artificial intelligence (AI) have revolutionized valve grinding machines, making them more efficient and precise. Modern valve grinders are equipped with CNC controls and automated systems that enhance operational consistency and reduce human error. These innovations enable manufacturers to achieve higher precision in valve grinding, improving the overall quality of industrial valves. AI-driven diagnostics and predictive maintenance capabilities allow manufacturers to monitor the condition of their machines in real-time, further enhancing operational efficiency and reducing downtime.

The shift towards smart manufacturing, powered by the Internet of Things (IoT), is also accelerating the adoption of advanced valve grinding machines. These machines can now be integrated into larger automated systems that provide real-time data, enabling operators to monitor performance and detect issues before they lead to failure. IoT-enabled valve grinding machines support predictive maintenance, which can predict and prevent potential breakdowns by analyzing machine performance data. This technological integration is essential for industries aiming to improve efficiency, reduce costs, and increase the reliability of their systems.

Technological advancements in grinding materials and techniques have improved the efficiency and precision of valve grinding machines. The introduction of advanced abrasive materials, such as diamond-based wheels, has allowed for smoother finishes and higher precision grinding. These materials are ideal for grinding high-performance valve systems in sectors like aerospace and automotive, where even the smallest imperfection can affect functionality. The continual development of these grinding technologies is pushing the capabilities of valve grinding machines and expanding their use in more demanding industrial applications.

Advancement | Description | Impact on Valve Grinding Machines |

Automation & AI Integration | Integration of AI for predictive maintenance and CNC controls | Enhances precision, reduces human error, and improves efficiency |

IoT-enabled Smart Manufacturing | Real-time diagnostics and monitoring through IoT technology | Enables predictive maintenance and operational optimization |

Advances in Grinding Materials | Use of materials like diamond abrasives for improved grinding results | Increases precision and smooth finishes |

As industrial operations expand, particularly in emerging economies, the need for precision manufacturing tools, including valve grinding machines, is increasing. In countries like China and India, the rapid development of infrastructure and manufacturing facilities is driving the demand for industrial machinery maintenance, including the use of valve grinding machines. The growth of industries like automotive, energy, and manufacturing in these regions is expected to lead to sustained demand for valve grinders.

As industries face stricter regulatory compliance and safety standards, the need for precision tools like valve grinding machines becomes more critical. In sectors such as aerospace, automotive, and energy, regulatory bodies require regular inspections and maintenance of components like valves to ensure safety and performance standards are met. Valve grinding machines help manufacturers comply with these regulations by ensuring that valves are ground to precise specifications, maintaining operational safety and compliance.

Industries are increasingly turning to valve grinding machines as a cost-effective solution for regular maintenance. These machines reduce the need for costly replacements and downtime by ensuring that valves are properly maintained and restored to optimal conditions. As industries seek to optimize operational costs, investing in advanced valve grinding machines offers a long-term solution for minimizing maintenance costs while ensuring the reliability of critical systems.

When selecting a valve grinding machine, it’s essential to consider factors such as precision requirements, machine type, and operational flexibility. The right machine should align with the specific needs of the industry, whether it’s for high-volume production or more specialized applications. Additionally, factors like ease of maintenance, machine durability, and support services from manufacturers should be taken into account to ensure long-term value.

There are several types of valve grinding machines, including manual, CNC-controlled, and automated grinders. Manual grinders offer simplicity and lower upfront costs but require more labor and can be less precise. CNC-controlled grinders offer higher precision and efficiency, making them ideal for high-volume applications. Automated machines, often integrated with AI and IoT technologies, provide the highest level of precision and operational efficiency, making them suitable for industries that require maximum output and minimal downtime.

Investing in valve grinding machines can have a significant upfront cost, especially for CNC and automated models. However, the long-term benefits, such as reduced downtime, lower maintenance costs, and improved operational efficiency, often outweigh the initial investment. Companies should consider the total cost of ownership, including maintenance, consumables, and energy consumption, to determine the ROI for their specific applications.

Machine Type | Advantages | Best for |

Manual Valve Grinder | Lower initial cost, simple to operate | Small-scale operations, less complex valve systems |

CNC Valve Grinder | High precision, repeatability, automated operations | Large-scale production, high-precision applications |

Automated Valve Grinder | Fully automated, high speed, minimal human input | High-volume industries, reducing operational downtime |

The valve grinding machine market is expected to continue growing as industries demand more precise and efficient solutions. Advancements in technology, particularly the integration of AI, automation, and IoT, will drive the demand for these machines. The rising focus on preventive maintenance and the growing need for high-performance industrial systems will ensure sustained growth in the valve grinding machine market.

Emerging markets, especially in the Asia-Pacific region, are expected to drive significant growth in the demand for valve grinding machines. As countries like China, India, and Vietnam expand their industrial and manufacturing capabilities, the need for precision maintenance tools will increase. The global expansion of manufacturing facilities and the growth of the automotive, aerospace, and energy sectors will continue to fuel the demand for valve grinding machines worldwide.

The rising demand for advanced valve grinding machines is driven by industries seeking precision, efficiency, and reliability in valve systems. Technological advancements like automation, AI integration, and smart manufacturing have enhanced these machines' capabilities. As industries focus on reducing downtime, optimizing maintenance, and meeting regulatory standards, valve grinding machines will continue to play a vital role in maintaining high-performance systems. Suzhou Jianuohao International Trade Co., Ltd. offers innovative valve grinding machines designed to improve efficiency and precision in industrial applications.

A: Valve grinding machines are used to restore and maintain the precision of valves by grinding their surfaces to ensure proper sealing and functionality in industrial systems.

A: The demand for valve grinding machines is rising due to the need for precision, efficiency, and reliability in industries such as automotive, aerospace, and manufacturing.

A: Valve grinding machines improve operations by reducing downtime, enhancing valve performance, and extending the lifespan of valve systems, which are crucial in high-demand industries.

A: Automated valve grinding machines offer enhanced precision, reduced human error, and increased productivity, making them ideal for modern industrial manufacturing.

A: Industries such as automotive, aerospace, industrial manufacturing, and marine heavily rely on valve grinding machines for maintaining high-performance systems.

A: AI integration in valve grinding machines helps optimize operations, improve precision, and enable predictive maintenance, further enhancing machine efficiency and reliability.