T: +86-512-66294696

E: sales@tzjmachine.com

E: sales@tzjmachine.com

Add: No.20, Guangdian Road, Guangfu Town, Wuzhong District, Suzhou, China

Views: 0 Author: Site Editor Publish Time: 2025-11-28 Origin: Site

Valve grinding machines are essential in maintaining valves, which are crucial to industrial operations. These machines ensure valves perform optimally, preventing failures that could disrupt processes. As industries demand more precision, cutting-edge valve grinding technology is transforming maintenance. In this article, we’ll explore how advanced valve grinding machines are revolutionizing valve maintenance and shaping its future.

For years, traditional valve grinding methods were widely used to repair and maintain valve components. These methods involved manual grinding, which, though effective, often lacked precision and efficiency. Operators relied heavily on their skills, and the grinding process was time-consuming. Early valve grinders also lacked advanced controls, making it difficult to achieve the required tolerances for optimal valve performance.

However, as industrial demands increased and the need for higher precision became critical, valve grinding machines evolved. Older methods, while still in use today for basic applications, have given way to machines capable of producing more accurate and consistent results.

Modern valve grinding machines have significantly benefited from technological advancements. The introduction of CNC (Computer Numerical Control), automation, and artificial intelligence (AI) has redefined the grinding process. These innovations allow machines to grind valve components with incredible precision, even to micrometric tolerances.

CNC-controlled valve grinding machines are capable of performing complex operations automatically, reducing human error and increasing consistency. Automation allows for faster processing times, ensuring that the valves are ground quickly while maintaining quality. These advancements are shaping the future of valve maintenance, allowing for faster, more reliable, and cost-effective operations.

Modern valve grinding machines come equipped with advanced grinding heads and tools that ensure superior precision. These tools are designed to handle a wide range of valve types and sizes, providing the flexibility to accommodate varying demands across industries. The grinding heads are engineered for accuracy, with adaptive features that adjust based on the material hardness, ensuring smooth, high-quality finishes on valve seats and faces.

For instance, diamond abrasives, known for their durability and sharpness, are often used in advanced machines. These abrasive materials are key to achieving the fine surface finishes required in industries where even minor imperfections can cause failures.

Automation has brought significant improvements in valve grinding. The integration of CNC technology allows for consistent, repeatable results without the need for constant human input. By programming the machine to perform specific tasks, operators can ensure that every valve receives the same level of precision.

CNC-controlled valve grinders can adjust automatically for different grinding depths, feed rates, and speeds, making them highly adaptable to various valve types and applications. This enhances the overall productivity of the valve grinding process, reducing downtime and labor costs.

With the rise of Industry 4.0, valve grinding machines are increasingly equipped with smart features and IoT (Internet of Things) capabilities. These machines can now communicate with centralized systems, allowing operators to monitor the grinding process in real-time. Sensors track variables such as temperature, pressure, and vibration, providing valuable data to optimize the grinding process.

This level of connectivity not only enhances the efficiency of the grinding process but also aids in predictive maintenance. By monitoring wear and tear on the machine’s components, operators can schedule maintenance before problems arise, extending the life of the equipment and reducing unplanned downtime.

Feature | Description | Benefit |

CNC Integration | Automation of grinding process with precise controls | Enhanced precision and reduced manual intervention |

AI & Machine Learning | Machine learning algorithms optimize grinding parameters | Continuous improvement in grinding quality and consistency |

IoT Integration | Real-time monitoring and predictive maintenance | Minimizes downtime and maximizes efficiency |

Advanced Grinding Heads | Adaptive grinding tools for different valve types | Ensures high precision across various valve sizes and materials |

One of the most significant benefits of advanced valve grinding machines is their ability to reduce downtime. Valve grinding is often required during routine maintenance or in response to valve failure. In either case, the faster and more efficiently the grinding process can be completed, the less downtime the system will experience.

Modern machines, with their high precision, ensure that the valve seats and faces are perfectly aligned, reducing the chances of future failures. This not only helps to extend the lifespan of the valves but also improves the overall reliability of the systems in which they are used.

The precision provided by advanced valve grinding machines directly impacts operational efficiency. For industries like automotive manufacturing, aerospace, and power generation, even the smallest errors in valve grinding can lead to significant problems, including reduced performance and higher failure rates. By ensuring that each valve is ground to exact specifications, these machines improve the performance of the entire system.

In aerospace, for example, the high precision of valve grinding is critical to maintaining the safety and efficiency of aircraft engines. A small imperfection in the valve surface could lead to engine failure, so having access to advanced grinding technology that guarantees perfection is essential.

In addition to improving precision and efficiency, cutting-edge valve grinding machines also help companies reduce maintenance and repair costs. By minimizing the risk of human error and improving machine reliability, these machines make valve maintenance more predictable and cost-effective. Predictive maintenance technologies further reduce costs by helping businesses avoid expensive, unexpected repairs.

Benefit | Description | Example Impact |

Reduced Downtime | More efficient grinding reduces machine repair time | Increased operational time in industries like automotive and aerospace |

Cost-Effective Maintenance | Longer valve lifespan and fewer repairs reduce maintenance costs | Lower overall maintenance expenses for power generation plants |

Enhanced Precision | CNC and AI integration provide highly accurate valve surfaces | Improved performance and reduced risk of valve failure |

Environmental Sustainability | Energy-efficient machines with reduced waste | Complies with modern environmental regulations in industries |

Both the automotive and aerospace industries rely heavily on high-precision valve grinding. In automotive manufacturing, valve grinding ensures that engine valves operate at optimal efficiency, leading to better fuel efficiency and lower emissions. Aerospace companies use advanced valve grinding to meet the stringent precision standards required for engine components.

For example, the production of jet engines demands valves that can withstand extreme conditions. Valve grinding machines that provide micrometric precision are critical for the development of reliable, safe engines that power aircraft.

In the power generation sector, the integrity of valve systems is crucial to ensuring that power plants operate efficiently. Valve grinding machines help maintain the high-performance standards needed for steam, gas, and nuclear power systems. In industrial applications, from oil refineries to manufacturing plants, precise valve maintenance reduces downtime and enhances operational reliability.

Valve grinders are vital in the marine and oil & gas industries, where engine performance and the ability to regulate fluid flow are critical. Regular valve grinding ensures that valves remain in optimal condition to prevent leaks and system failures, especially in high-pressure systems used in the oil and gas sector.

Industry | Application | Benefit |

Automotive | Engine valve maintenance | Precision grinding ensures optimal engine performance |

Aerospace | Maintenance of aircraft engine valves | Enhances the reliability of critical engine components |

Power Generation | Valve maintenance for turbines and piping systems | Improves system efficiency and reduces unplanned shutdowns |

Marine & Oil & Gas | Maintenance of engine valves and offshore equipment | Extends the lifespan of valves in harsh environments |

Looking forward, AI and machine learning are set to revolutionize valve grinding machines further. AI can analyze data from grinding operations, optimizing settings in real-time to improve the grinding process. These systems will not only adapt to material variations but also predict the most efficient methods for grinding specific valve types.

As industries face increasing pressure to reduce their environmental footprint, valve grinding machines are evolving to be more energy-efficient. The demand for machines that consume less power while maintaining high precision is driving innovation in the industry. Modern machines incorporate energy-saving features such as advanced motor control and regenerative braking.

The future of valve grinding lies in connected, intelligent machines. With the growing adoption of Industry 4.0 technologies, valve grinders will be able to communicate with other industrial systems, sharing data that can be used to optimize the entire maintenance workflow. Real-time monitoring and data analytics will become the standard, helping operators maintain optimal valve conditions with minimal manual intervention.

One of the biggest barriers to adopting advanced valve grinding machines is the initial investment cost. These machines are often expensive, particularly when equipped with CNC controls and automation. However, the long-term benefits—such as reduced downtime, improved precision, and lower maintenance costs—make them a valuable investment for many industries.

Operating advanced valve grinding machines requires a skilled workforce. The integration of automation and CNC technology does not eliminate the need for skilled operators; rather, it changes the skill set required. Training and development programs will be essential for the next generation of valve grinding professionals.

As global industrialization continues to expand, the demand for advanced valve grinding machines is expected to grow. Emerging markets, particularly in Asia-Pacific, are poised to be key drivers of this growth. Industries in these regions are increasingly investing in modern machinery to improve production efficiency and product quality.

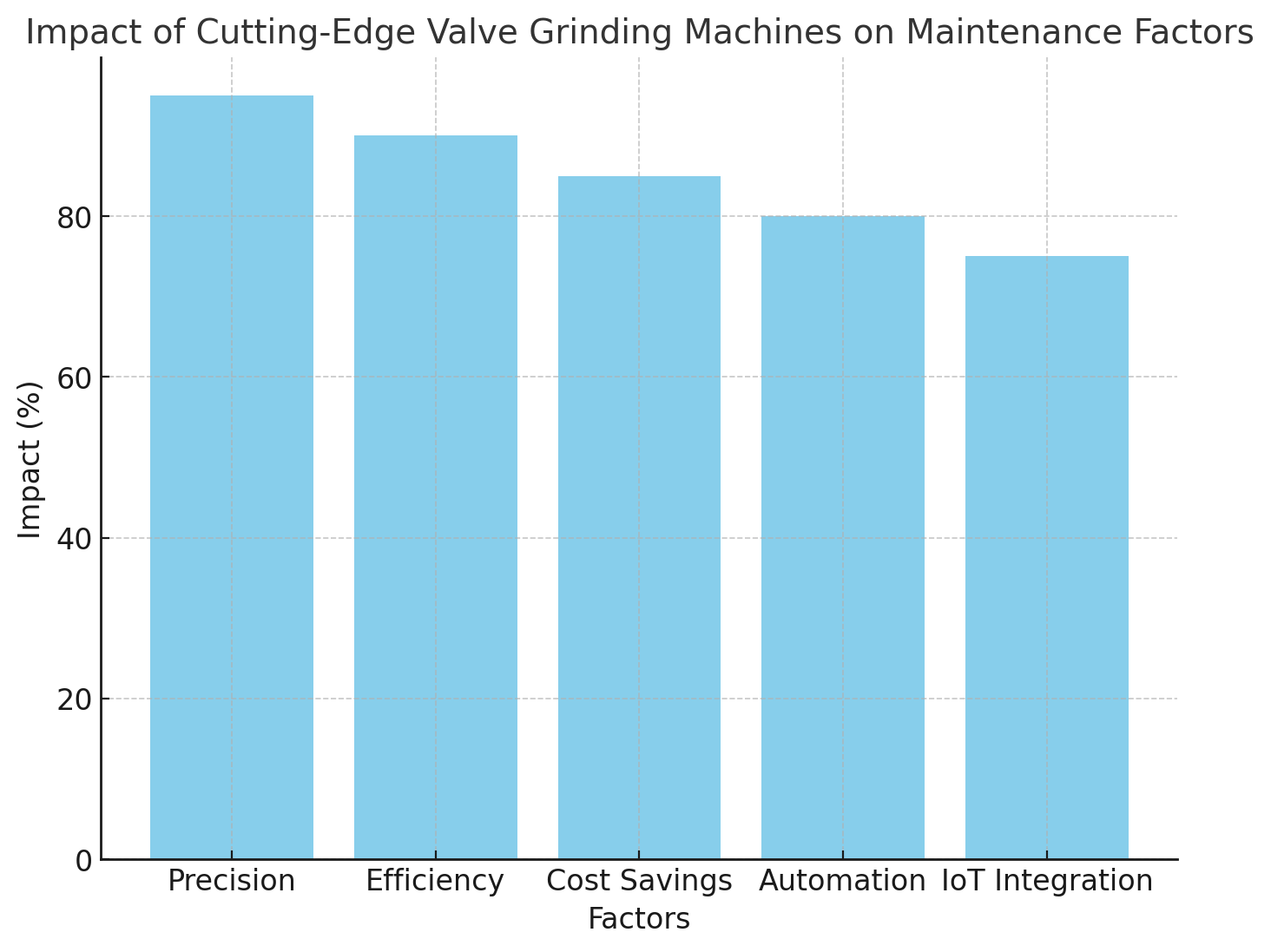

Advanced valve grinding machines are transforming valve maintenance with cutting-edge technologies like CNC controls, AI, and IoT. These innovations ensure precision, efficiency, and cost savings, benefiting industries such as automotive, aerospace, and power generation. Companies like Suzhou Jianuohao International Trade Co., Ltd. are leading the way by providing advanced solutions that enhance operational efficiency and help businesses stay competitive in their respective sectors.

A: Valve grinding machines are specialized tools used to smooth and shape valve surfaces. They ensure precision and efficiency in valve maintenance, preventing leaks and improving performance.

A: Modern valve grinding machines integrate technologies like CNC, AI, and IoT. These advancements enhance precision, reduce human error, and improve operational efficiency in valve maintenance.

A: Valve grinding machines are crucial for maintaining the precision of valve components in industries like automotive, aerospace, and power generation. They ensure valves function optimally and reduce downtime.

A: CNC-controlled valve grinding machines automate the grinding process, ensuring consistent and precise valve surfaces. This reduces manual intervention and improves the accuracy of the grinding operation.

A: Industries such as automotive, aerospace, power generation, and marine benefit from advanced valve grinding machines. These machines improve valve precision, extend service life, and reduce downtime in critical systems.