T: +86-512-66294696

E: sales@tzjmachine.com

E: sales@tzjmachine.com

Add: No.20, Guangdian Road, Guangfu Town, Wuzhong District, Suzhou, China

Views: 0 Author: Site Editor Publish Time: 2025-09-14 Origin: Site

CNC grinding has become a game-changer in modern manufacturing. It enables industries to create components with unmatched precision.This article will dive into the CNC grinding process, types, advantages, and applications, focusing on the importance of CNC Valve Grinding. You'll learn how CNC grinding can elevate the quality and efficiency of your manufacturing operations.

CNC grinding is a machining process that uses a grinding wheel, guided by a computer, to remove material from a workpiece. It allows for precise shaping and finishing of materials such as metals, ceramics, plastics, and composites. This process is essential in producing components with high precision, whether they are flat, cylindrical, or have internal features.

Programming: Engineers create a program using specialized software. The program specifies cutting depth, feed rates, grinding wheel size, and other crucial parameters.

Setup: The workpiece is securely positioned in the CNC grinding machine, ensuring stability during the grinding process.

Grinding Process: The CNC system controls the grinding wheel's movements, removing material and achieving the desired shape and finish.

Inspection: Post-grinding, the workpiece undergoes precise measurement to ensure it meets required specifications.

Post-Processing: Depending on the application, additional steps like deburring or polishing may be applied.

CNC grinding isn't a one-size-fits-all process. There are several types of grinding, each suited for specific tasks and materials.

This process involves grinding a flat surface on the workpiece to achieve a smooth and uniform finish. It's particularly useful for producing tight-tolerance flat surfaces.

Used for machining cylindrical or rod-shaped components, this method removes material along the length of the workpiece, achieving precise diameter and surface finishes.

In this process, the workpiece is placed between two grinding wheels. One wheel controls the workpiece's speed, while the other removes material to achieve the desired shape. It is particularly efficient for high-volume production of cylindrical parts.

Internal grinding focuses on the inner surfaces of holes or bores within a workpiece. This is crucial for parts like bearings and valves, where internal precision is critical.

This is a specialized surface grinding technique, where material is removed at a slow feed rate to machine deep slots or complex profiles.

CNC grinding offers numerous benefits to manufacturers, making it a preferred method for high-precision machining.

One of the key CNC grinding advantages is its ability to achieve extremely tight tolerances, often within a few microns. This makes it an ideal choice for industries that require the highest level of accuracy, such as aerospace, medical devices, and automotive components like CNC valve grinding.

CNC grinding creates smooth, defect-free surfaces. This is especially important for applications where surface quality plays a significant role, such as producing high-performance automotive engine components or medical tools.

CNC grinding can be used to process a wide range of materials, including hard-to-machine metals, ceramics, plastics, and composites. This versatility makes it ideal for custom parts production.

Despite the high precision, CNC grinding is an efficient process. Once programmed, the machines can run autonomously, reducing the need for human intervention and lowering labor costs. Additionally, it minimizes material waste due to its precision.

Tip: If your production process involves components like valves or gears, CNC valve grinding can significantly improve your production efficiency and part quality, reducing long-term operational costs.

CNC grinding is integral to many industries, delivering precise components that meet high standards. Let’s explore some of the primary industries where CNC grinding is used.

CNC grinders are used to manufacture precision parts such as engine components, brake systems, and transmission parts. The precision and repeatability of CNC grinding ensure that these critical parts function reliably in high-stress conditions.

In aerospace, CNC grinding is essential for producing complex components with tight tolerances. Aircraft parts, such as landing gear components, turbine blades, and other high-performance components, rely on CNC grinding to meet the rigorous safety and performance standards.

CNC grinding plays a key role in creating medical devices and components like surgical instruments, implants, and precision tools. The precise machining capabilities of CNC grinding ensure that medical components meet strict safety, hygiene, and performance standards.

CNC grinders are commonly used in tool and mold-making, where precision is critical. CNC grinding ensures that cutting tools, molds, and dies are produced with the necessary sharpness and durability for efficient manufacturing processes.

Tip: CNC valve grinding is commonly used in automotive and industrial applications, where valves must meet specific performance criteria. High-precision grinding ensures that valves function smoothly under extreme conditions.

Valve components, particularly those used in automotive engines, require precision grinding to ensure proper sealing and functionality. CNC valve grinding is particularly valuable for shaping the seating surfaces of engine valves, ensuring they are smooth and uniformly finished for optimal performance.

In industries like automotive, where engine efficiency and longevity are crucial, CNC valve grinding ensures tight tolerances and a high-quality surface finish that improves engine performance, reduces wear, and increases the lifespan of critical components.

Precision Grinding: CNC machines use a specialized grinding wheel to shape the valve seat, removing material precisely to ensure a perfect seal.

Consistency: The automated nature of CNC grinding ensures that every valve is shaped to the same high standard, making it ideal for mass production.

Efficiency: CNC valve grinding reduces the amount of time required to achieve precise valve dimensions, improving overall productivity in manufacturing.

Tip: For industries that rely on engine performance, such as automotive and aerospace, integrating CNC valve grinding into your manufacturing process will enhance component quality, reduce defects, and ensure efficient production.

CNC grinding has revolutionized precision manufacturing, offering high accuracy, versatility, and efficiency. Whether used in the CNC valve grinding process for automotive engines or achieving fine finishes for medical instruments, CNC grinding is crucial in industries demanding precision. The various processes, types, and applications discussed emphasize its importance in modern manufacturing.

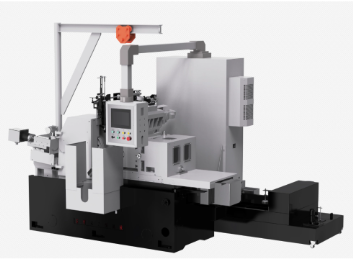

By embracing CNC grinding technology, such as the solutions offered by Tianzhijiao Machinery , manufacturers can achieve high-quality, cost-effective, and efficient production. This will help meet stringent quality standards and boost production speed. Understanding CNC grinding's processes, advantages, and specific applications like CNC valve grinding enables manufacturers to enhance the precision, performance, and reliability of their products.

A: CNC grinding is a precision machining process that uses computer-controlled grinding machines to achieve high accuracy and tight tolerances. It is essential in producing components for industries like automotive, aerospace, and medical.

A: CNC valve grinding utilizes computer-controlled machines to grind engine valves with high precision. This process ensures that the valves meet the exact specifications required for optimal engine performance.

A: CNC grinding offers several advantages, including high precision, automation, and efficiency. It allows manufacturers to create complex parts quickly while maintaining tight tolerances, especially in processes like CNC valve grinding.